Shaper Ryan Harris Is On a Mission to Prove That the Sport He Loves Can Clean Up Its Manufacturing Act

How toxic is your board?

-

CategoryPeople

-

Written byRobert Earle Howells

-

Photographed byJeff Berting

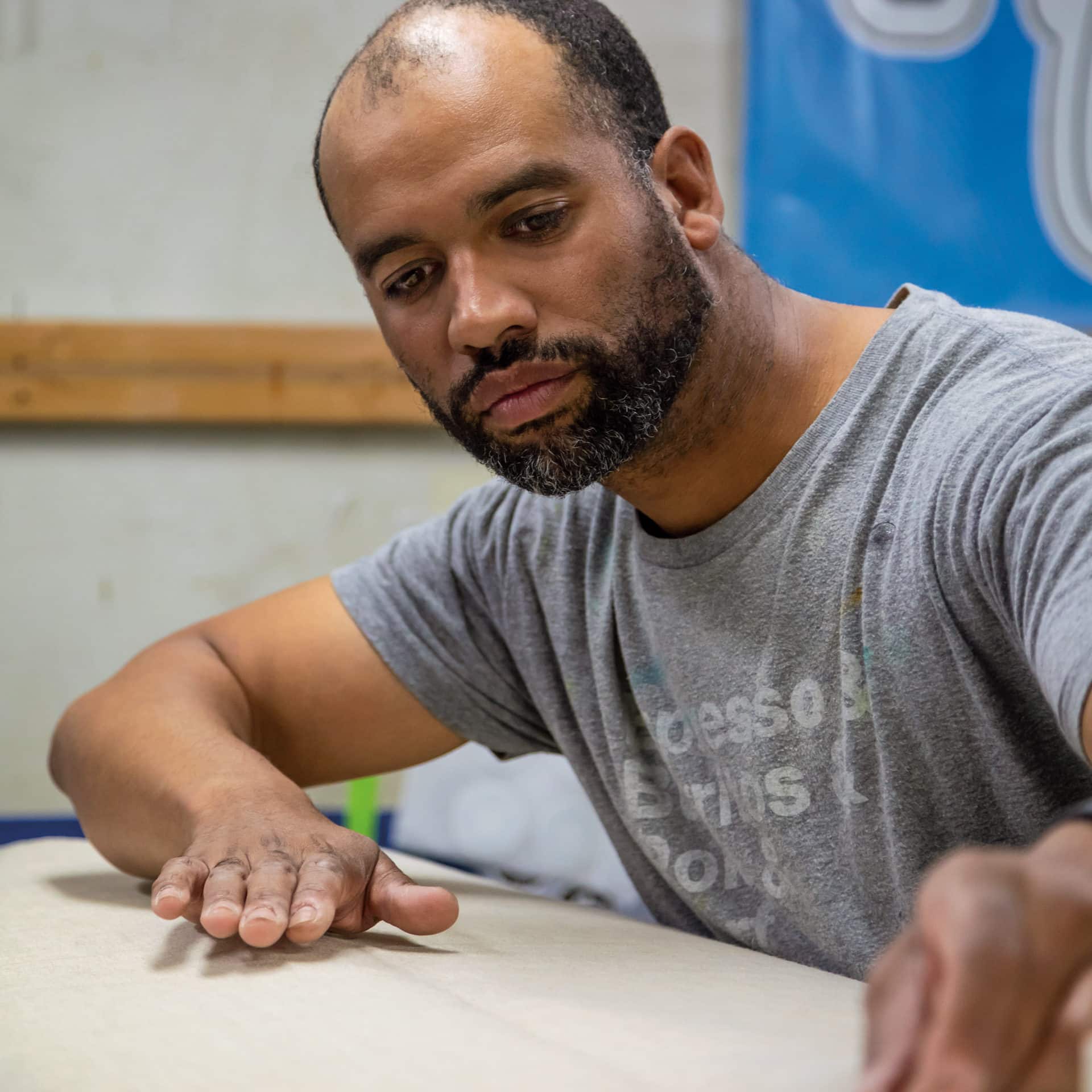

Ryan Harris is one of SoCal’s finest surfboard shapers, but what he’s most eager to show me in his south Torrance workshop are … his mealworms. “These frickin’ rad critters are going to save the planet,” he says.

Saving the planet is very much on Ryan’s mind, and his strategy extends beyond curating some 10,000 mealworms. He also makes environmentally sustainable surfboards in what he calls “the only zero-waste surf-production factory on the planet.”

To understand the significance of that, you have to understand surfing’s dirty little secret: Most surfboards are toxic. They’re made from polyurethane foam—toxic, not recyclable—coated generously with toxic polyurethane resin. One serious meeting with some rocks at El Porto, and that shattered plank of toxicity heads off to the nearest landfill to molder its carcinogenic components into the earth we call home.

It doesn’t have to be that way, contends Ryan—40-year-old surfer, veteran shaper and head dude at Earth Technologies. “We use EPS [expanded polystyrene, aka Styrofoam] for our boards, 100% recyclable. And bio-epoxy resin. And we run our shop very similar to a recycling facility—what’s not recyclable is shredded and upcycled to new products.”

Which is why you’ll see, right next to the shaping stands at Earth Tech, thin round molds filled with excess resin. Shredded bits of almost anything get mixed into the resin inside the molds, where they harden into slender discs, then get backed with sustainable, self-adhering cork (no smelly glue in this joint). Voila: surf-themed coasters for sale. Ryan is also beginning to take orders for barroom countertops made of the same upcycled stuff.

This is also why a venerated station in the shop is devoted to the care and feeding of those frickin’ rad mealworms. These chubby squirmers, you see, are never happier than when they’re digesting EPS foam.

What? You thought EPS isn’t recyclable? The contrary evidence is right before my eyes, where Ryan is holding a chunk of foam riddled with mealworms making Swiss cheese of the stuff. The byproduct of their digestive efforts becomes organic gardening material.

By now I suspect that anyone who surfs has their eyebrows raised. Surfers are all about the environment, sure. But they’re also about their boards, and if these so-called ecoboards don’t perform like the real thing, well, surfers are going to stick with their dirty little secret.

Ryan is accustomed to overcoming surfers’ skepticism. “I’m as much educator as shaper,” he says. “This is an industry largely stuck in the way they did things 60 years ago. But the truth is, our core material is not only sustainable, it’s stronger. Our boards may go for $100 or so more than conventional boards—biopoxy is expensive—but our boards are going to last twice as long.”

And, of course, should you break one of Ryan’s ecoboards, you can bring it back and know that it will be 100% recycled.

Leading the Revolution

Ryan Harris came to surfing a bit late. He grew up in Portland, Oregon, where he skied and snowboarded at Mount Hood and fished with his dad. “It was all beautiful. I was groomed as an environmentalist from the beginning.”

He bailed out of a postcollege Nike job designing footwear, moved to the South Bay at age 21 and fell in love with surfing. El Porto was, and still is, his main go-to.

“I fell into doing repairs,” Ryan says, “and buddies told me, ‘You’re decent at this—you should try shaping.’ I started shaping boards for friends at first as a hobby, then a full-time career. I was an airbrush guy at a poly shop”—meaning he’s worked with his share of toxic materials—“so I know what I’m talking about. The eco thing happened about seven to eight years into it.”

Ryan was among the first shapers to use bio-epoxy, or biopoxy, which was notorious back then for going yellow after a time. “I didn’t care that it was yellow—just that the boards were stronger and didn’t break.” Biopoxy no longer yellows, he stresses.

Ryan may be at the vanguard of the sustainable-surf movement, but he’s not alone. A national organization called Sustainable Surf, also based in SoCal, advocates for eco-sensitive board construction and certifies shapers who meet its standards. Those who comply with minimal standards get the Ecoboard Level One designation. Those who meet higher standards in both materials and manufacturing process are rewarded with the Ecoboard Gold Level certification. Ryan was the first shaper ever to earn the Gold standard.

“Ry Harris was one of the first to commit 100% to making ecoboards,” says Sustainable Surf cofounder Kevin Whilden. “That was key. Back in 2012 he was one of the only glassers to make ecoboards. He showed that he could make high performance boards that work well and were sustainable. So many surf companies started using him—and they still do—but back then he was the only resource.”

Today dozens of board makers, including makers of stand-up paddleboards, windsurf boards and kiteboards, have Sustainable Surf certification. But Ryan’s commitment to zero waste in his workshop puts him in something of a different category.

“Ry is doing it all over again,” says Kevin. “Number one was to show that you could use sustainable materials that don’t affect performance or quality. Number two is Ry’s focus on zero waste, on upcycling and recycling. So again, he’s a leader, an innovator setting an example for everyone else in the surf world.”

Still, only about 10% of surfboards made today are considered environmentally sustainable. “But it’s changing,” says Kevin. “That’s a big jump from 1% six or seven years ago. In another five years it will be, ‘Why wouldn’t I do that?’ But if not for Sustainable Surf and Ry Harris, it wouldn’t even be close to where we are now.”

You Might Smell Food

Back in the Earth Technologies shop—in a nondescript, light-industrial complex off South Sepulveda in Torrance—Ryan is pulling a sheet of thin fiberglass over a SUP board and bathing it in biopoxy. He is wearing disposable gloves but no respirator.

OSHA needn’t have a cow over the latter fact, because this is a VOC-free shop. No volatile organic compounds—the stuff you smell in paints, thinners, glues, etc. And in poly-based resins. “Yeah, nothing smells here,” Ryan says. “Well, you might smell food sometimes.”

The surf industry “loses guys to cancer every year,” according to Ryan, “guys who have been shaping with toxic poly resins.”

Only in one workshop room do Ryan and his coworkers wear masks, and that’s in the airtight shaping room where foam blanks are shaped and sanded into surfboards. That, of course, creates particulates in the air that eventually settle to the floor, as do bigger chunks of foam. What happens to those sweepings? Worm food, of course.

Those disposable gloves Ryan is wearing will get tossed into the drip trays beneath the board-shaping stations, along with strips of masking tape, to get coated with excess resin and harden into odd-looking blobs. No, that’s not worm food, but it gets fed into the shop’s industrial-strength shredder—an impressive beast that’s between R2-D2 and C-3PO in size. Those shavings go into making coasters and countertops and whatever else Ryan and his crew come up with (e.g., hand planes for bodysurfing, fins and key chains.)

In fact, Ryan calls his coworkers “zero-waste technicians.” Because in Ryan’s world, “making a coaster is just as important as glassing a surfboard.”

Waves of Success

Ryan will be the first to tell you that it’s not easy to make a living as a board shaper, let alone one dedicated to making sustainable boards. “The running joke around here is that margins so suck on surfboards that we’ll end up making money from our trash.”

Still, Ryan is on target to make 1,000 boards this year, plus he and the crew do private-label work for other board manufacturers. He’s fresh off a big trade show and so swamped with orders that his voicemail cautions callers that he doesn’t talk during working hours. Hilton has ordered no fewer than 400 decorative ecoboards that will hang on the walls of a Westside hotel.

And Ryan has gained notoriety among surf cognoscenti, including pro surfer Hunter Jones and former pro and current World Surf League commissioner Jessi Miley-Dyer. “We call them ecoboard ambassadors,” Ryan says.

It’s all part of his campaign to overcome a skeptical marketplace. “Most surfers give a shit about the environment, or we wouldn’t have a sport. So they’re becoming more and more open, especially when they see a pro on something eco. We did a foilboard for [pro surfer] John John Florence. Now we’re doing lots of them.”

He’s also upping his tech game with new board blanks imbued with strong composite stringers that permit careful tuning of a board’s flex pattern. But Ryan doesn’t geek out too much on topics like that. The performance of his boards speaks for itself.

He will geek out endlessly about zero waste (“We don’t even have a dumpster anymore”), upcycling, recycling and, of course, mealworms. He tosses a chunk of agave into a bin crawling with foam-eating critters. “Gotta keep ’em hydrated.”

Ventura Blvd is part of the Golden State network, a family of digital, social and print media brands celebrating the people, pursuits, lifestyles and ideas of California. In every issue going forward, we will share one story from across our network. Each will explore topics that go beyond the limits of the San Fernando Valley. These are California stories that speak to the meaningful impact our state and its residents make on the global stage. To learn more about Golden State and to see more stories like this, please visit goldenstate.is

Join the Valley Community